Energy

Applied AI

Product & Design

AI-Enhanced Motor Inspection for Drilling Operations

Motor inspections were inconsistent and hard to standardize, leading to unreliable recommendations in drilling operations. Arionkoder partnered with Turnco to evolve AI-Fit™, an AI-powered motor inspection system that improves accuracy, consistency, and decision-making in the field.

Motor inspections were inconsistent and hard to standardize, leading to unreliable recommendations in drilling operations. Arionkoder partnered with Turnco to evolve AI-Fit™, an AI-powered motor inspection system that improves accuracy, consistency, and decision-making in the field.

Energy

Applied AI

Product & Design

AI-Enhanced Motor Inspection for Drilling Operations

Motor inspections were inconsistent and hard to standardize, leading to unreliable recommendations in drilling operations. Arionkoder partnered with Turnco to evolve AI-Fit™, an AI-powered motor inspection system that improves accuracy, consistency, and decision-making in the field.

ALIGN

AI-Fit™ was created to modernize motor inspection reporting, helping drilling companies make better decisions based on data that reflects real drilling conditions.

While the system already had a functioning ML model, missing documentation and inconsistent input data were limiting its reliability.

We began with an in-depth discovery workshop, bringing together AI, product, and design teams to understand how inspectors worked in the field and how inspection data directly influenced model outputs.

ALIGN

AI-Fit™ was created to modernize motor inspection reporting, helping drilling companies make better decisions based on data that reflects real drilling conditions.

While the system already had a functioning ML model, missing documentation and inconsistent input data were limiting its reliability.

We began with an in-depth discovery workshop, bringing together AI, product, and design teams to understand how inspectors worked in the field and how inspection data directly influenced model outputs.

ALIGN

AI-Fit™ was created to modernize motor inspection reporting, helping drilling companies make better decisions based on data that reflects real drilling conditions.

While the system already had a functioning ML model, missing documentation and inconsistent input data were limiting its reliability.

We began with an in-depth discovery workshop, bringing together AI, product, and design teams to understand how inspectors worked in the field and how inspection data directly influenced model outputs.

PRIORITIZE

Through discovery, we identified two critical challenges:

Model reliability: inspection data lacked structure, documentation, and consistent inputs.

Inspector experience: the reporting interface made it easy to introduce errors and hard to understand results at a glance.

Improving accuracy required addressing both the AI pipeline and the human workflows feeding it.

PRIORITIZE

Through discovery, we identified two critical challenges:

Model reliability: inspection data lacked structure, documentation, and consistent inputs.

Inspector experience: the reporting interface made it easy to introduce errors and hard to understand results at a glance.

Improving accuracy required addressing both the AI pipeline and the human workflows feeding it.

PRIORITIZE

Through discovery, we identified two critical challenges:

Model reliability: inspection data lacked structure, documentation, and consistent inputs.

Inspector experience: the reporting interface made it easy to introduce errors and hard to understand results at a glance.

Improving accuracy required addressing both the AI pipeline and the human workflows feeding it.

Prove

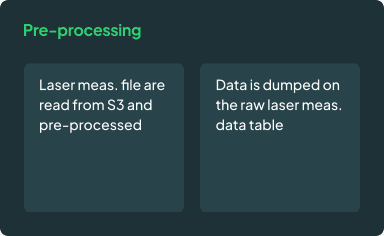

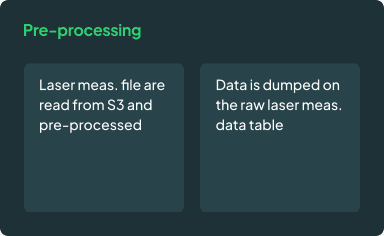

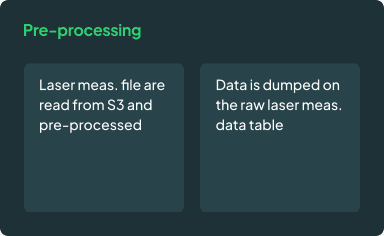

Our ML experts refined and optimized the existing model by reviewing datasets, documenting selected features, and improving ML workflows.

New pipelines were introduced to incorporate feedback from the inspection app as model input.

At the same time, our product and design teams reworked the inspection flow. Guiding details were added to help inspectors enter more reliable data, and the UI was redesigned for clarity and speed.

The result was a refined ML model that combines manual measurements with data backed by over a decade of scientific field research — delivering accurate recommendations in 95% of cases.

Prove

Our ML experts refined and optimized the existing model by reviewing datasets, documenting selected features, and improving ML workflows.

New pipelines were introduced to incorporate feedback from the inspection app as model input.

At the same time, our product and design teams reworked the inspection flow. Guiding details were added to help inspectors enter more reliable data, and the UI was redesigned for clarity and speed.

The result was a refined ML model that combines manual measurements with data backed by over a decade of scientific field research — delivering accurate recommendations in 95% of cases.

Prove

Our ML experts refined and optimized the existing model by reviewing datasets, documenting selected features, and improving ML workflows.

New pipelines were introduced to incorporate feedback from the inspection app as model input.

At the same time, our product and design teams reworked the inspection flow. Guiding details were added to help inspectors enter more reliable data, and the UI was redesigned for clarity and speed.

The result was a refined ML model that combines manual measurements with data backed by over a decade of scientific field research — delivering accurate recommendations in 95% of cases.

Integrate

We integrated these improvements into a working inspection platform used in real drilling contexts.

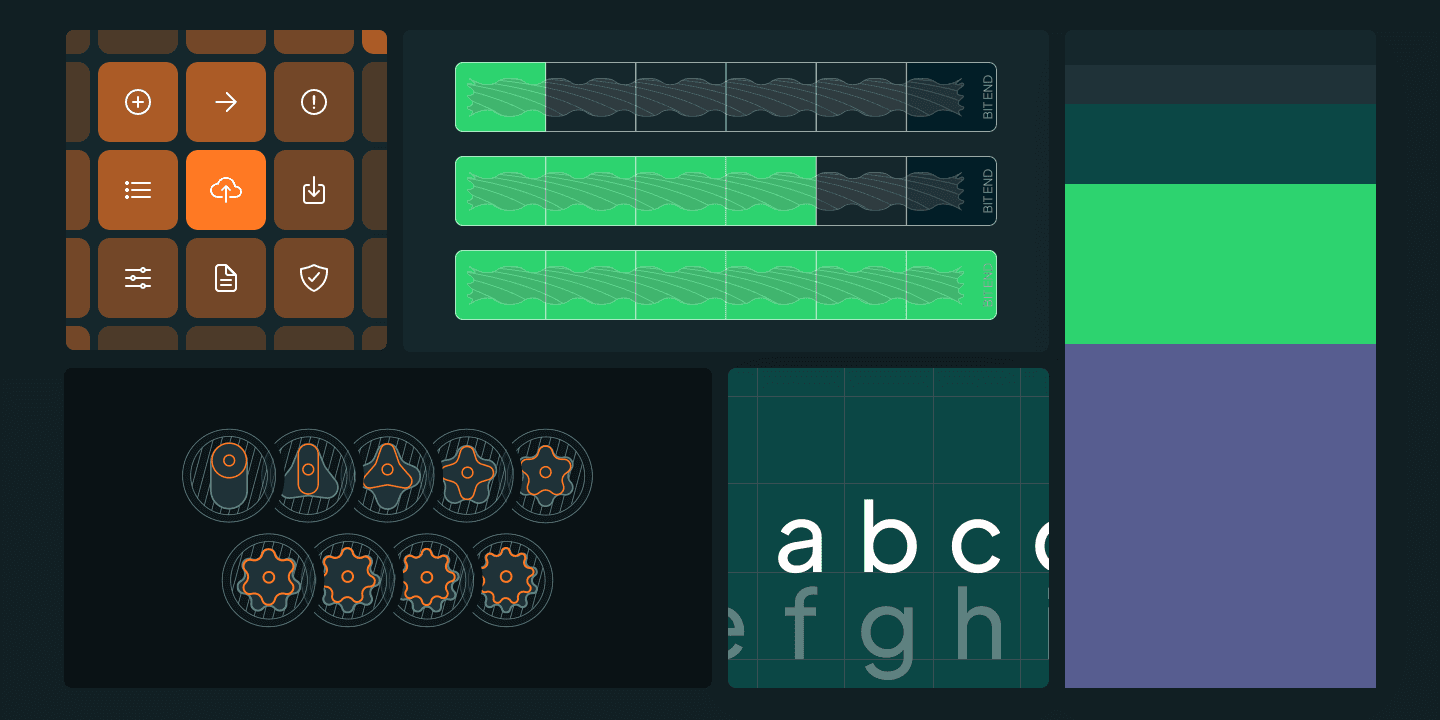

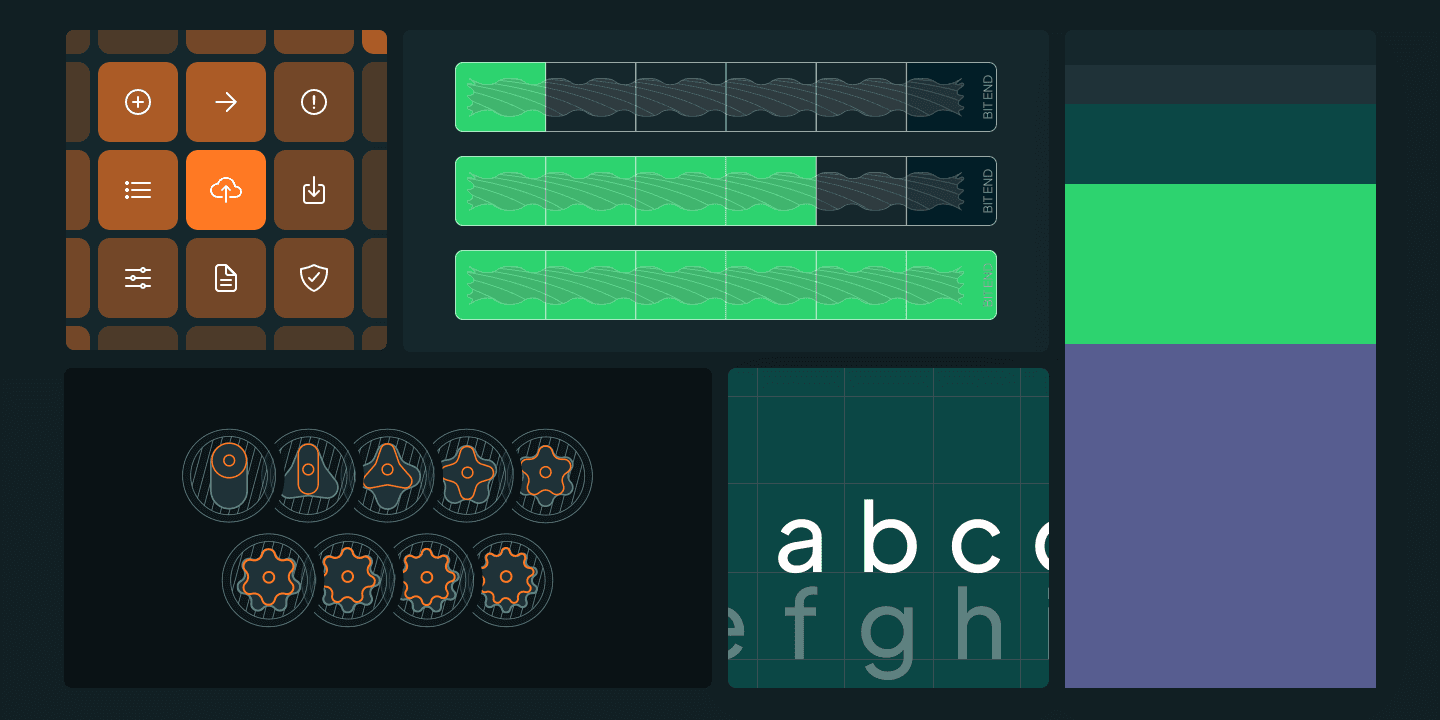

A high-performance UI was built by combining existing chart libraries with custom components, making inspection reports easier to read and interpret.

To further reduce errors, the design team introduced custom icons representing each possible rotor-stator combination, allowing inspectors to quickly recognize configurations and validate inputs.

Integrate

We integrated these improvements into a working inspection platform used in real drilling contexts.

A high-performance UI was built by combining existing chart libraries with custom components, making inspection reports easier to read and interpret.

To further reduce errors, the design team introduced custom icons representing each possible rotor-stator combination, allowing inspectors to quickly recognize configurations and validate inputs.

Integrate

We integrated these improvements into a working inspection platform used in real drilling contexts.

A high-performance UI was built by combining existing chart libraries with custom components, making inspection reports easier to read and interpret.

To further reduce errors, the design team introduced custom icons representing each possible rotor-stator combination, allowing inspectors to quickly recognize configurations and validate inputs.

Scale

AI-Fit™ is part of a broader product suite. To support scale and long-term consistency, Arionkoder created a shared UI component library using Storybook.

This reduced UI maintenance, ensured consistency across products, and made it easier to evolve the platform over time.

With a clearer data foundation, a stronger model, and a scalable UI system, AI-Fit™ is positioned to continue improving inspection accuracy as usage grows.

Scale

AI-Fit™ is part of a broader product suite. To support scale and long-term consistency, Arionkoder created a shared UI component library using Storybook.

This reduced UI maintenance, ensured consistency across products, and made it easier to evolve the platform over time.

With a clearer data foundation, a stronger model, and a scalable UI system, AI-Fit™ is positioned to continue improving inspection accuracy as usage grows.

Scale

AI-Fit™ is part of a broader product suite. To support scale and long-term consistency, Arionkoder created a shared UI component library using Storybook.

This reduced UI maintenance, ensured consistency across products, and made it easier to evolve the platform over time.

With a clearer data foundation, a stronger model, and a scalable UI system, AI-Fit™ is positioned to continue improving inspection accuracy as usage grows.

“Arionkoder is everything I could’ve asked for. The people I work with is what makes Arionkoder great. They’ve been excellent at meeting deadlines, staying on budget, and communicating with us.”

Lonnie Smith

President

@

Turnco and Founder of AI-Fit™

How we helped:

1.

Refined and documented an existing ML model and data pipelines

2.

Improved inspection data quality through UX and workflow design

3.

Designed a clear, high-performance reporting interface

4.

Built a shared UI component library for scalability

5.

Connected field workflows with AI reliability

Team

Product Manager & Facilitator UX/UI Designer ML Experts Back-End Engineers

Delivery

UX/UI Design ML Pipeline Refinement Infrastructure & Solution Architecture Working Inspection Platform Development Forecast

GET STARTED

Ready to make AI useful?

Ready to make AI useful?

Ready to make AI useful?

Turning bold ambition into lasting impact starts with a conversation.

Turning bold ambition into lasting impact starts with a conversation.

© 2025 Arionkoder.

All rights reserved.

Quick Actions

Jump to Value

The Foundry

Email: hello@arionkoder.com

Offices: Americas · EMEA (5 offices)

This site respects your device’s accessibility settings, including Reduce Motion, and reduces animations when that option is enabled.